Rebuilds

Sandvik rebuilds support your most vital equipment throughout their life cycles.

Equipment rebuilds

Custom rebuilds

In our Custom rebuilds, your equipment is inspected by certified specialists, following OEM criteria’s and expertise, that defines the right scope for the specific machine intervention.

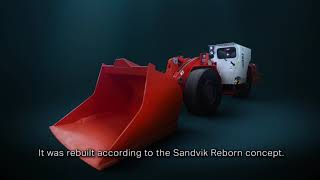

Reborn

In our Reborn solutions we offer a full scope rebuild with pre-engineered kits, forecastable and produced in our factories and shipped to one of our workshop facilities.

Life extension

In our Life Extension solutions you choose which modules to rebuild. We use pre-engineered kits, forecastable and produced in our factories and shipped to one of our workshop facilities.

Downloads

Download rebuilds brochure (PDF)

-

Optimum time for a rebuild intervention

-

Plan your interventions and count on Sandvik worldwide

New lease of life makes sense for mining equipment

The need to ‘reduce, reuse and recycle’ is now widely accepted – but did you know that equipment rebuilds can also reduce fuel consumption, Total Cost of Ownership (TCO), downtime and accidents, in addition to carbon footprint?

My Sandvik digital services

Our Sandvik fleet telematics solution

As part of a rebuild, we can retrofit our Knowledge Box™ to enable your machine to send data. Benefit from gaining visibility of machine health, performance and fleet utilization based on the actual machine data.

Talk to our experts about how we can help you today