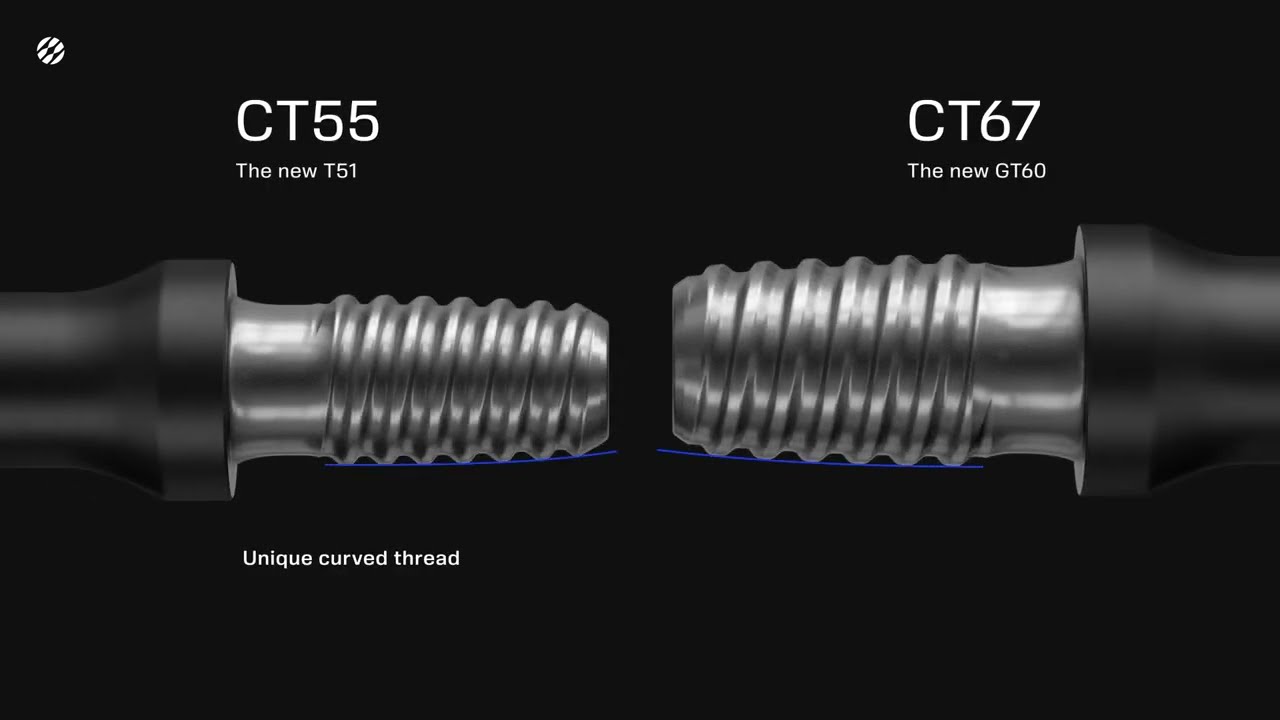

CT55 and CT67

CT55 and CT67 for surface

- Hole diameter CT55 (new T51)

- 89.0 - 127.0 mm (3.5 - 5.0 in.)

- Hole diameter CT67 (new GT60)

- 102.0 - 152.0 mm (4.0 - 6.0 in.)

- Flushing house

- 70 mm (DXi), 80 mm (DPi), 90 mm (DPi)

CT55 and CT67 curved thread systems are designed for surface mining and quarrying. These systems accommodate higher drilling power than the standard ones and feature a curved profile that reduces stress levels strategically while optimizing the product for fatigue strength.

Features

-

Patented design

The unique, patented curved thread system provides a bigger X-section where needed and significantly reduces stress levels. This leads to fewer breakages and increased service life.

-

Productivity boost

The curved threads achieve a faster rate of penetration per meter and more meters per engine hour. These factors - along with problem-free drilling, easy coupling/uncoupling and good hole quality/hole straightness - provide increased productivity during drilling operations.

-

Advanced technology

The specially developed shoulder-driven system achieves an efficient energy transfer along with a stiff, strong connection. Easy coupling/uncoupling leads to minimal rattling.

Product specifications

- Hole diameter CT55 (new T51)

- 89.0 - 127.0 mm (3.5 - 5.0 in.)

- Hole diameter CT67 (new GT60)

- 102.0 - 152.0 mm (4.0 - 6.0 in.)

- Flushing house

- 70 mm (DXi), 80 mm (DPi), 90 mm (DPi)

- Rock drills CT55 (new T51)

- RD925, RD927, RD930

- Rock drills CT67 (new GT60)

- RD927, RD930, HL1060T, HL1560T, RD1635FC

Curved thread innovation

Packed with power

Learn how a curved top hammer thread makes all the difference. The CT55 and CT67 bench drilling tool systems give you a lower cost per drilled meter and a significant reduction in total drilling expenses. Check out other features, benefits and values.

Can't find the answer to your questions?

Are you looking for a spare part or component?