Everything seems slow compared to our new push bore reamers

Reduce costs and enhance efficiency

Our push bore reamers are designed to make time work in your favor. Combine improved ROP, minimized downtime and simplified in-field service operations to elevate your performance with this latest innovation from Sandvik.

Extra hours of productivity per year

Results from product testing, may vary depending on

ground and drilling conditions.

Service life for cutters

Upgraded for a new level of performance

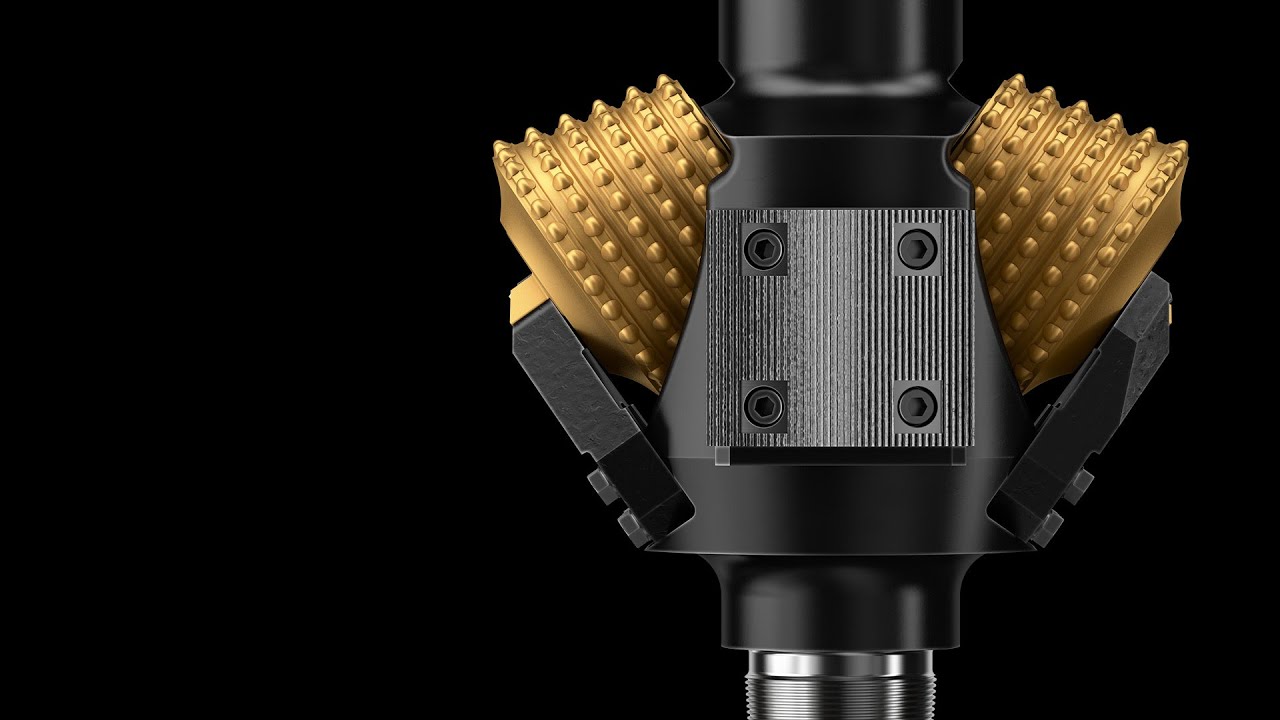

Introducing our new push bore reamers and cutter, uniquely manufactured and specially equipped for efficient push bore reaming of slot holes in underground mining. The system includes two Ø740 mm reamers for both up and down operations and a fit-for-purpose developed cutter.

Ensure market leading performance, save valuable time and unlock cost savings. The push bore reamer system features simplified in-field servicing with its bolt-on items, and optimized productivity through longer service life, reduced downtime, and higher ROP. Also experience the positive safety effects for your operators by minimized manual handling of equipment over time, as well as the sustainability benefits with your reduced transportation needs.

Results from testing

Test information

- The black bar represents the results of our previous reamer model

- The gold bar represents the results of our new reamer model

- Product development done during a three year period to ensure constant improvements

- Wear pads have been replaced with new design, from welded to bolted

This cutting-edge tool will accelerate your progress, ensure longer tool life and simplify your in-field operations

Russell Clayton

Product Manager Raise Boring, Rock Tools Division

Download the folder

Push bore reamers folder (PDF)Questions and answers

-

What are the main upgraded design features?

Key upgrades include simplified in-field service with bolted-on wing and wear pads, and a patented saddle design for better material clearing in the cutter pocket. The cutter itself is equipped with a tougher carbide grade, a steeper cone angle on the shell allowing for less skidding and carbide damage, as well as an improved bearing design and more heat-tolerant grease.

-

What benefits will this bring for my slot hole drilling?

The results from the product testing confirms lower cost of drilling and major time savings with improved ROP and simplified maintenance. All components are bolted on and replaceable when worn, so local in-field servicing is possible, and the reduction of transportation costs and emissions are evident. A positive safety impact is the minimized operator exposure due to fewer cutter changes and less handling of the equipment over time.

Both our up and down Ø740 reamers also utilize identical spare part components as far as practically possible, and this sufficiently reduces inventory demands when you plan to drill with both reamers.

-

Is this new system compatible with all rigs?

Yes, this system is compatible with most raise bore rigs - including the Rhino 100 - which are equipped with a 10" drill rod and 8 1/4" DI 22 connection